BIM vs Digital Twin: What’s the Difference and Why It Matters

If you are attending any modern construction meeting today from a weekly design coordination call to a facility handover talk you are likely hearing two terms more often than ever before: “We already have the BIM model” and “We should be thinking in terms of building a digital twin”. These two ideas are frequently conflated and many professionals seem to assume that as soon as they have a BIM model the second their project achieves practical completion it turns into a digital twin.

But in their collective quest to make buildings smarter, more efficient and more sustainable, owners, developers, operators and even product makers all share the desire for a better operating experience. Here’s the truth that at some point everyone had no choice but to acknowledge: BIM is not a digital twin (to be fair I’d argue it’s not much of anything by itself) and whatever it was initially built to do or become, in today’s construction environment, the digital twin concept extends far beyond anything BIM was ever meant to accomplish.

The Digital Twin Concept Explained: How a Building’s Living Model Works

To grasp the change over time consider this scenario: Two identical office towers are built in the same year. Each one had pretty perfect BIM models made during design and construction with all the 3D geometry, coordinated MEP layouts, asset metadata, schedules. Everything that makes up a well thought out BIM execution plan. But when the buildings opened they followed very different paths. In Building A the BIM file gathered digital dust on some server environment, occasionally brought up in isolation and most of the time forgotten as the real building faced the daily complexities of HVAC fluctuations, energy demands, occupant movements and maintenance challenges.

In Building B, however, the BIM model didn’t go to sleep. It evolved. It was connected to IoT sensors, linked to the building management system, updated continuously with performance data, and enhanced with analytics. Over time, it transformed into a digital twin, a living model that mirrors the building in real time. And because of this transformation, Building B didn’t just exist. It learned, adapted, and improved. After a year, the contrast is dramatic. Building A struggles with unpredictable energy peaks, unexpected equipment failures, and recurring comfort issues reported by tenants. Building B, meanwhile, feels almost self-aware. It detects inefficiencies instantly. It simulates different HVAC strategies digitally before operators try them in the real world. It predicts chiller failures days in advance. It continuously updates its digital representation based on real-time data. The BIM models for both buildings started the same way, but only one was elevated by digital twin technology.

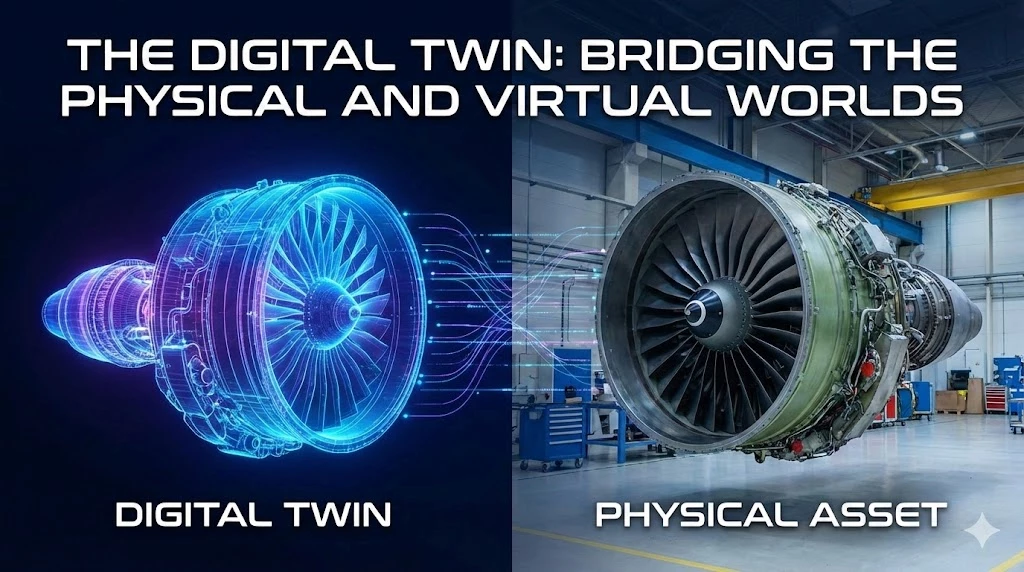

Layers of a Digital Twin: Physical Asset, Digital Replica and Data Environment

So what is the digital twin idea and why is it transforming the built world with such speed? At its most basic level, a digital twin is a dynamic real-time digital model of a building or system that receives data from the operational systems it represents. It is not like the traditional modeling in which you freeze it. It grows with the building. It is receiving information from what’s happening now not the way it may have been planned six or 12 months ago.

The digital twin meaning in construction has become even deeper as buildings have become smarter. Today, a digital twin is not just a representation of walls, ducts, equipment, or rooms. It is a constantly updated ecosystem of information built from three essential layers:

- Physical Asset – The building itself, its HVAC systems, equipment, structure, lighting, elevators, and all components that make up the real-world environment.

- Digital Replica – Often begins as a BIM model but then evolves far beyond design geometry into an operational, data-rich environment.

- Data Connection Layer – IoT sensors feeding live measurements, API connections streaming operational data, cloud analytics processing patterns, and dashboards visualizing real-time building performance.

Without this continuous flow of information, a digital twin is just another digital model. With it, the twin becomes an intelligent system.

Why Digital Twin Technology Is Valuable for Smarter, Sustainable Buildings

The construction industry is under pressure from rising utility costs, tougher sustainability regulations, labor shortages, and increased expectations for comfort and uptime. Buildings have more systems than ever, and their performance affects everything—from tenant satisfaction to ESG reporting to long-term asset value.

A digital twin acts as the building’s “central nervous system,” giving operators unprecedented visibility into performance. It can show room-by-room energy use, airflow patterns, equipment health, occupancy trends, and even simulate how the building would behave under different conditions. This kind of insight simply isn’t possible with a traditional BIM model, no matter how detailed it is.

Digital Twin vs BIM: Key Differences Between Design Models and Living Systems

To appreciate how far the digital twin goes beyond BIM, it helps to revisit what BIM actually is. Building Information Modeling is a method of creating digital representations of physical and functional characteristics of a building. It’s essential for design coordination, clash detection, cost estimation, and construction planning.

But BIM’s primary role ends when construction ends. It represents design intent—not real-time operations. A BIM model doesn’t automatically update when a pump fails, a room temperature fluctuates, or occupancy patterns shift. It doesn’t monitor performance. It doesn’t predict failures. It doesn’t analyze or optimize anything on its own. It is static by nature.

This is the key distinction in the digital twin vs BIM conversation. BIM is the foundation. The digital twin is the evolution. BIM helps you design the building correctly. The digital twin helps you operate the building intelligently. BIM is a snapshot. A digital twin is a livestream. BIM is manual. A digital twin updates itself. BIM stops at handover. A digital twin begins at handover and continues for decades.

Owners, developers, and operators are moving beyond BIM into digital twin systems. They want visibility, predictability, sustainability, cost efficiency, automation, and long-term control. They want to know how their buildings behave—not how they were designed to behave. They want models that learn from data, not ones that gather dust.

How Digital Twins Actually Work: Core Components and Engineering Workflow

When people first hear the phrase digital twin technology, they often imagine something highly futuristic almost sci-fi. But the truth is far more practical: a digital twin is built from everyday building systems, common data sources, and familiar engineering workflows. The magic isn’t in one flashy tool but in how all the different layers connect to form a living, evolving model. In this part, we’ll walk through how a digital twin really works, how BIM becomes a twin, and what digital twinning platforms, software, tools, and engineering practices are involved in its development. And we’ll do it through a long-form story that follows a real building through its transformation.

From BIM to Digital Twin: How a Building Comes to Life Through Data

Imagine a new corporate headquarters nearing completion. For years, architects and engineers have refined the BIM model structural framing, MEP layouts, asset parameters, equipment families, and construction phases. The BIM model is impressive, but it still represents a moment in time. Nothing in it updates automatically. It’s a digital reflection of design intent, not performance. Now picture the developer wants more. They want a building that doesn’t just exist; they want a building that learns. That is where digital twin development begins.

The first step is creating a digital replication of the building this is where the BIM model is polished, cleaned, enriched, and readied for the operational world. Engineers filter out construction-only content and focus on assets that will matter throughout the building’s lifecycle: chillers, AHUs, pumps, meters, lighting zones, occupancy areas, valves, dampers, and more. This process is often handled by digital twin engineering specialists who understand both BIM and operational technology. But the story doesn’t get interesting until the building is fully connected.

Where Digital Twin With Data Truly Begins: Sensors, Connectivity and Real-Time Insight

Before opening day, contractors begin installing IoT sensors temperature, humidity, CO₂, occupancy, vibration, energy, water flow. These are not just gadgets; they’re the building’s sensory organs. While the BIM model gives us the body, the IoT layer gives us the senses. And once these sensors are online, data starts flowing in real time.

- Air temperature in Zone B-15 rises unexpectedly? The digital twin knows.

- A pump shows early signs of vibration fatigue at 4:17 pm? The twin knows.

- Power consumption spikes in the west wing after 6 pm? The twin knows.

This is what transforms a BIM dataset into a real-time digital twin with data. It becomes more than geometry it becomes insight.

To handle all this information, the building uses a digital twin platform, a cloud-based environment where live data streams meet the digital model. These platforms often host:

- Real-time dashboards

- Data visualizations

- Asset health monitoring

- Predictive analytics

- Energy usage trends

- Maintenance insights

- Occupancy behavior patterns

Some platforms integrate directly with digital twin software specializing in simulation airflow simulation, energy modeling, equipment behavior prediction, and fault detection. These simulation tools, often called digital twin simulation software, give the building the ability to test scenarios, not just display data.

For example, if a facility team is thinking about reducing airflow in Level 7 to save energy, they can simulate it first. If sustainability teams want to know the impact of changing cooling schedules, they test it in the twin. This is where the digital twin becomes a decision-making partner.

Digital Twin Tech Stack: The Four Pillars of Real-Time Intelligence

Behind the scenes, a digital twin relies on multiple technology layers. Let’s follow the building’s first day of operations:

As the building comes to life, multiple data layers begin feeding the digital twin. Each layer adds depth, accuracy, and intelligence—turning a static model into a living system.

1. IoT Sensors & Equipment Data

By 8 am, thousands of live readings are already streaming into the twin, capturing the building’s pulse:

- Temperature from every zone

- Humidity from every floor

- Energy loads from distribution panels

- Vibration from rotating equipment

- CO₂ levels from meeting rooms

- Occupancy counts from common areas

This is the raw energy that fuels the digital twin’s awareness.

2. Building Management System (BMS) Integration

By noon, the BMS starts enriching the twin with deeper operational behavior:

- Chiller status

- AHU performance metrics

- Damper positions

- Pump RPM

- Fan power consumption

- Valve opening percentages

This layer unlocks process-level digital twin capabilities, showing how systems interact end-to-end.

3. API Connectors & Cloud Services

Throughout the day, the twin pulls in external and contextual data through APIs:

- Utility consumption data

- Weather and climate insights

- Historical performance logs

- Maintenance schedules

- Energy tariffs and pricing signals

This ecosystem transforms the model into a data-driven digital twin that understands both internal dynamics and external influences.

4. AI & Predictive Analytics

By evening, AI models begin recognizing patterns—cooling cycles, occupancy fluctuations, early equipment anomalies. Over time, the twin evolves into an AI-powered digital twin, capable of predicting issues long before they surface.

This is the moment the digital twin begins to think ahead, not just report.

Digital Twin Software, Tools and Platforms

As the building operates, different layers of technology step in to handle specific responsibilities within the digital twin ecosystem. Each one contributes to how the building is monitored, analyzed, and optimized.

Digital Twin Platforms

These manage the real-time experience—dashboards, alerts, data ingestion, device connectivity, and the interfaces that teams interact with every day. Popular platform examples include Azure Digital Twins and PTC ThingWorx.

Digital Twin Software

Focused on intelligence and computation, this software drives advanced analytics, asset modeling, predictive maintenance, and simulation workflows. Leading examples include Siemens MindSphere and Bentley iTwin.

Digital Twin Tools

Supporting components that handle data cleaning, model preparation, IoT setup, visualization, and stream configuration—keeping the twin healthy and consistent. Developers often rely on tools like Eclipse Ditto or Apache IoTDB to manage IoT and digital twin data pipelines.

Digital Twin Solutions

Comprehensive offerings that combine software, engineering integration, system setup, and monitoring—ideal for organizations needing end-to-end support. Solution providers such as Dassault Systèmes offer integrated ecosystems spanning simulation, modeling, and operations.

Digital Twin Services

Provided by consultants, integrators, and tech firms, these services span design, deployment, lifecycle management, and optimization of the digital twin. Companies like Accenture and Capgemini support large-scale implementations across industries.

While many vendors claim to offer the “best” digital twin software, the right choice depends entirely on your building’s complexity, systems, and long-term data goals. For high-fidelity integration or immersive visual environments, partnering with a digital twin development company—or using visualization capabilities from an Unreal Engine development company like Epic Games—can elevate the entire experience.

A Real Example: The Building Learns About Itself

After three months, the digital twin begins to reveal patterns no one noticed before:

- An AHU operating 20% harder than expected, hinting at a potential blockage.

- Underused meeting rooms, allowing operators to reduce airflow and cut energy consumption.

- East-facing offices heating faster in the morning, triggering automatic cooling adjustments.

- Equipment inefficiencies detected long before humans would notice them.

This is not BIM. This is not static modeling. This is living digital replication—where the building stops being passive and becomes an active participant in its own improvement.

Implementing Digital Twins: Tools, Solutions, and the Future of Smart Buildings

After exploring how a digital twin works and how BIM evolves into a living model, the next step is understanding how to implement one effectively. While the technology is powerful, the real value comes from integrating platforms, software, tools, and engineering processes into one operational ecosystem.

Choosing the Right Digital Twin Platform and Software

Not all digital twin platforms are created equal. Some focus heavily on visualization and dashboards, while others excel in engineering-grade analytics and simulation. When evaluating platforms—whether it’s Azure Digital Twins, PTC ThingWorx, or Siemens MindSphere—consider these three pillars:

- Integration capabilities: Can it ingest IoT, BMS, energy meters, and occupancy data seamlessly?

- Analytics & simulation: Does it support predictive analytics or integrate with simulation engines such as Bentley iTwin?

- Lifecycle management: Does it support the full digital twin journey from design to operations?

Beyond platforms, specialized tools like Eclipse Ditto, Apache IoTDB, or visualization engines like Unreal Engine handle data pipelines, modeling, visualization, and optimization workflows.

To accelerate deployment, many organizations partner with a digital twin development company or integrate immersive simulation using Unreal Engine development teams.

The Role of Digital Twin Services and Integrators

Many organizations lack the internal expertise to build and manage a digital twin end-to-end. This is where digital twin integrators and service providers—including firms like Accenture, Capgemini, or Dassault Systèmes—play a critical role.

- Installing IoT sensors and establishing connectivity

- Setting up process digital twin workflows

- Integrating historical + real-time operational data

- Training teams on dashboards and simulations

- Ensuring cybersecurity, compliance, and continuous support

Their involvement ensures your digital twin isn’t just a model—it becomes a functional, operational intelligence system.

Examples of Digital Twin Solutions in Action

A high-rise office building originally using BIM integrates hundreds of IoT sensors for HVAC, energy, and lighting. Within months, digital twin solutions reduce operational costs, prevent equipment failures, and improve tenant satisfaction.

A manufacturing facility uses digital twin manufacturing software to monitor production lines. Simulation and predictive analytics reduce downtime, improve throughput, and cut waste dramatically.

These examples show that digital twins aren’t limited to new construction—they can be retrofitted into existing buildings with massive impact.

The Benefits of a Fully Functional Digital Twin

- Operational efficiency through real-time optimization

- Predictive maintenance that reduces downtime

- Data-driven decision making backed by simulations

- Sustainability improvements that support ESG goals

- Enhanced occupant experience and comfort

Digital Twin Integration with BIM

BIM is the foundation, but not the twin. A BIM-to-digital twin workflow requires:

- Asset metadata

- Real-time data streams

- IoT and BMS connectivity

- Simulation and analytics capabilities

Once connected, BIM becomes a living, data-driven digital twin—bridging design intent with operational reality.

Future of Digital Twins in Construction and Operations

Digital twins are becoming standard across buildings, industrial facilities, and cities. Key trends include:

- AI-driven predictive analytics for autonomous operations

- City-scale digital replication for resource optimization

- Integration with smart grids and renewable systems

- Lifecycle-focused platforms spanning design to end-of-life

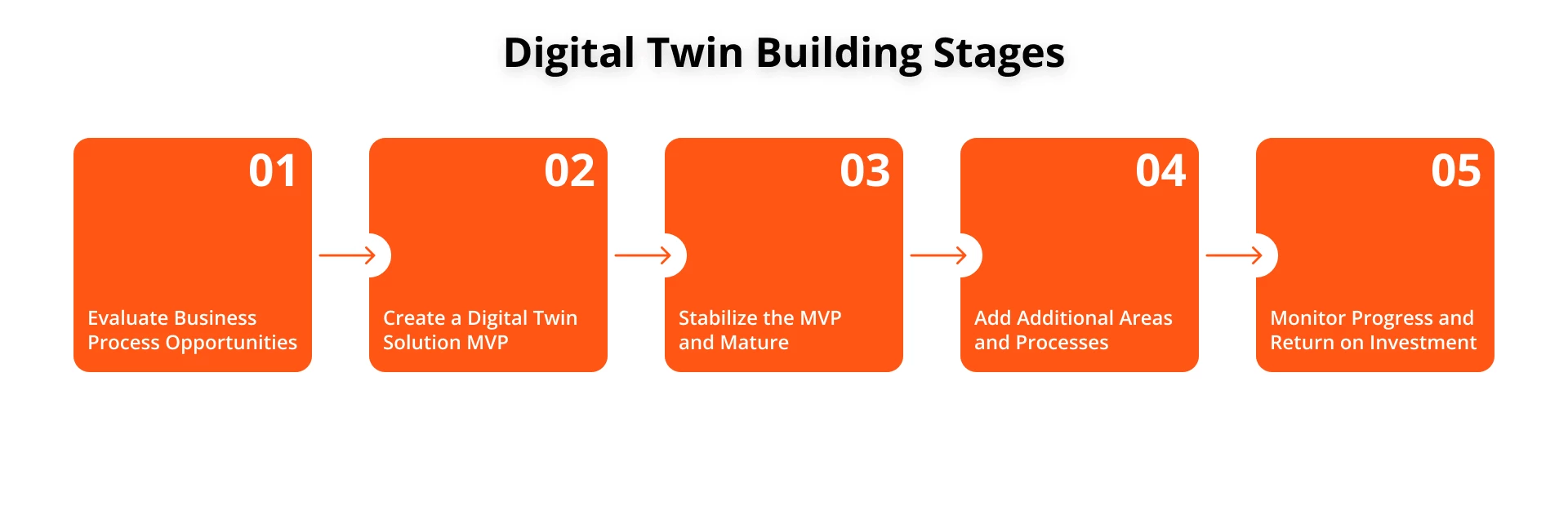

How to Start Creating a Digital Twin Today

- Assess assets and systems

- Select the right platform and software

- Engage digital twin integrators or service providers

- Connect BIM to real-time operational data

- Implement simulation and predictive analytics

Conclusion: Beyond BIM Into a Smarter Future

The journey from BIM to a sensor-connected, AI-enhanced digital twin is transformative. With the right combination of platforms, software, tools, services, and integrators, buildings no longer just exist—they continuously learn, adapt, and optimize.

Ready to Transform Your Building with a Digital Twin?

Implementing a digital twin may seem complex, but the rewards are significant. At Atlyx, we help organizations transition from static models to intelligent, real-time digital ecosystems powered by analytics, automation, and immersive visualization.

If you’re exploring digital twin strategies—whether for visualization, data integration, IoT optimization, or full-lifecycle intelligence—we design systems built for scale and long-term performance. Begin your journey toward smarter operations and discover what your building can become.

e2bet89

December 27, 2025 at 4:50 pmJust browsing around and saw e2bet89. Seems like another decent online betting option. The bonuses are pretty tempting! Worth a look, I think. Learn more at e2bet89.

phdream 7

February 2, 2026 at 3:14 pmPhdream 7 is a fun little distraction when I’m bored. Graphics are pretty good and the gameplay is smooth enough. Check it out at phdream 7.